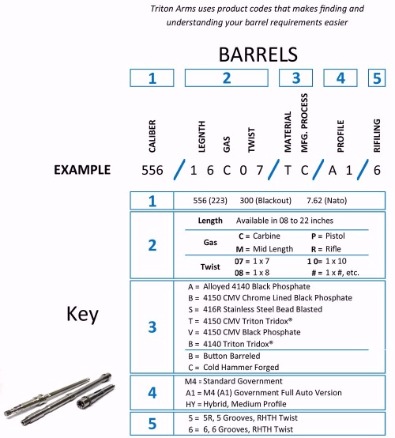

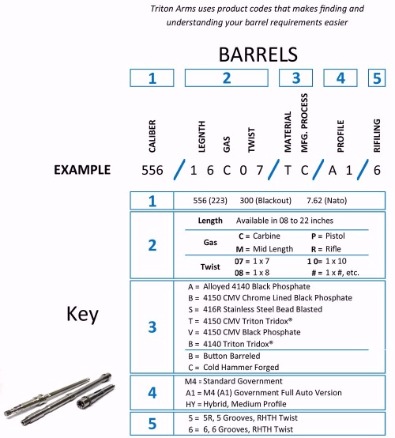

Triton Arms “Original Armory” Barrels, How Do We Build The Best!

If

you are shopping for your first AR-15 or considering building your own, you may

be wondering why so many look the same but costs differ greatly, or what makes

a rifle more accurate or reliable than the next? One answer and maybe the most

important is barrels. The most critical part of the weapon as it relates to

accuracy, longevity, and ultimately reliability is the barrel. With the following guides and a little

information hopefully we can help you to understand what makes barrels better,

and why Triton Arms “Original Armory” barrels make the Difference!

First let’s look at the materials used in manufacturing

41xx

steel is a family of SAE steel

grades, as specified by the Society of Automotive Engineers (SAE). They have an

excellent strength to weight ratio and are considerably stronger and harder

than standard 1020 steel. Chrome Moly, and Chrome Moly Vanadium added or (CMV)

are some of the most common types of materials we see on the market today. This

type of steel is a hard, strong steel that comes in several forms of 41xx,

including 4130, 4140, and 4150. The higher the number in the last two digits,

equals higher Chrome content and harder steel. 4150 CMV is a Mil-Spec Standard

acceptable for use in the United States Military, and Law Enforcement Agencies.

The Vanadium adds strength, toughness and heat resistance to the metal making

it more suitable for excessive temperatures and use for long periods of time.

This allows for better and more reliable performance in Heavy Use, Full auto

and Burst applications as compared to the lower 4140 or 4130 Chrome-Moly.

Stainless Steel is another metal with high Chromium content which makes it less

susceptible to corrosion, it is a softer or more malleable metal, much

slicker, and as such, allows for more precision machining in the manufacturing

process. More precision, and tighter tolerances, equate to better accuracy and

better performing for ballistics, which is why 416R Stainless Steel is the

standard for barrel making for match, or competition grade barrels. While it

offers better corrosion resistance it is not corrosion proof, depending on the

finish it may require minimal maintenance to keep it performing and looking

good.

Now let’s examine the rifling and finishing processes

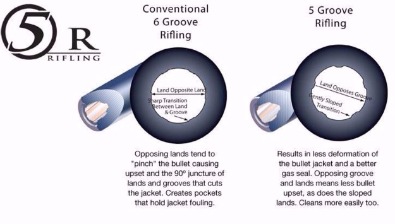

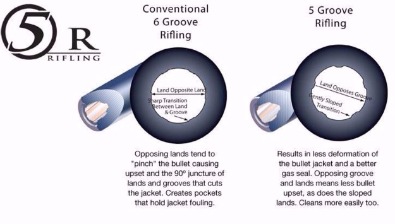

Conventional rifling has most often used 6 groove and

while it is the standard, some companies have ventured in to 4 and 3 groove.

Six groove has over the longer period of time produced the most consistent

ballistics and accuracy results, and arguably 4 groove challenges those

results. While there are subtle differences between the two, most agree that

there is very little difference in their performance. With the recent

introduction of 5R rifling a new dimension has been added that not only

provides better accuracy, velocity and trajectory, but cleaner more durable

performance overall. For semi-auto and full-auto applications in particular,

the durability and anti fouling capabilities of 5R are proving to be far

superior. The 5R is a 5 groove rifling with lands and grooves opposing each

other. Therefore eliminating bullet pinch and allowing a more true flight path

with less resistance or drag on the projectile. This in turn allows for better

accuracy, and higher velocity. The R part of the equation is for a radiused

or angled relief as opposed to a hard 90 degree cut between the grooves and

lands as it is in conventional rifling. This allows for less fouling of copper

and jacket material in the grooves providing more consistent flight, and a

better gas seal which again results in higher velocities and more reliable,

accurate operation.

e now combine these elements with the finishing

process which is equally as important to the performance of the barrel. Many

barrel manufacturers simply coat there barrels with Black Phosphate or Bluing.

An in-expensive processes that gives the barrel a nice black finish. They

provide little or no protection to the inside of the barrel very little to the

outside. They require constant maintenance, abrade easily and wear significantly

over time. Highly susceptible to corrosion and rust particularly in harsh

climates. Chrome lining was brought along to provide lubricity, ease of

cleaning and corrosion resistance to the interior of barrels, and as a result

is the Military standard for most applications today. Although chrome does

perform very well and is preferred my many competition shooters, and industry

agencies, performance deficiencies opened the door for new processes. Chrome

lining is an applied coating and a production product. Barrels have to be over bored

and chambered to allow for the application of hard chrome to bring it back to

the specification tolerances. Being an applied product it cannot be evenly

applied, which allows for inconsistent tolerances in the barrel and effects

both accuracy and velocity. Salt Bath Nitriding also known as Melonite,

Nitridox, or in our case TriDox®, is a ferritic nitrocarburizing process. With

this process we have again brought a new dimension to the world of semi-auto

and full-auto guns. Nitriding is not a coating or an applied product, but

rather a process that changes the surface of the metal on a molecular level. By

diffusionally adding nitrogen and carbon to the ferrous surface at temperatures

between 1000 -1075 degrees F. This process produces a compound layer that

provides lubricating properties to the surface. Corrosion resistance is greatly

increased in the Oxidation step of the process, which also produces a

cosmetically appealing matte black finish. Additionally the Rockwell hardness

is also increased proportionally to the alloy content of the barrel material,

usually a Rockwell rating between 65-70, as compared to a 4150 CMV Black

Phosphate, Chrome lined barrel at Rockwell 57. While Nitride is perceived as

new it has actually been in use for some time, by several companies. It has

gained recognition by many of U.S. Special Forces and is quickly becoming the

standard for many of their applications. The performance and ballistics are

outstanding, with exceptional wear and durability.

Ok so with all of this Information why does Triton Arms

“Original Armory” Barrels make the difference?

Triton

Arms Barrels are all made with either 4150 (CMV) Chrome Vanadium added steel or

416R Stainless Steel, the two finest barrel materials that are available.

Our rifle blanks are button rifled using state of the art equipment and old

world craftsmanship. We provide barrels in conventional 6 Groove and

Feature our 5R rifling as the “New Standard”. Each barrel is then CNC

machined utilizing the latest and most innovative CNC machines and

Turning Centers available today, to maintain strict tolerances and

concentricity throughout the manufacturing process. From profiling and

balancing each barrel is then Hand chambered, finish reamed, and head spaced to

exacting tolerances in accordance with SAAMI standards for specified

calibers. Barrels then undergo our formulated finishing process were they

are bead blasted and prepped for our Tridox® finish. Tridox® is our

proprietary QPQP Salt Bath

Nitriding process that bonds with the metal on a molecular level.

This treatment produces an extremely hard, slick surface that resists carbon

adhesion and increases corrosion resistance. Industry standards utilize generic

salt bath products and generally perform a QP (Quench & Polish) procedure.

Tridox® utilizes superior products and involves a QPQP (Quench Polish Quench Polish)

procedure which provides a superior finish, lubricity, and hardness of steel at

67-70 Rockwell. Extending a barrel's service life by reducing the friction

produced inside the bore, for a net decrease in bore surface wear over time.

Tridox® converts the barrel’s steel surface without any build-up, retaining all

of the benefits of traditional chrome lining, without suffering the accuracy

degradation commonly encountered with uneven application of chrome inside the

barrel's bore. The end result is a barrel that's capable of producing accuracy

on par with a match stainless steel tube, while also exhibiting the longevity

and resilience of a chrome lined, mil-spec barrel. It is this attention to

stringent specifications, and quality processing that allows Triton Arms to

offer a "Lifetime Warranty” and provides you with the highest level

of accuracy, velocity and energy of any barrel available on the market today!